Coke Technology

Heat Recovery Coke (HRC) Technology

Westbrook Thermal Technology has developed a truly advanced design for heat recovery cokemaking that includes ovens, machinery, and related facilities. Our technology originates from a vast amount of hands-on experience in design, construction, and start-ups which spans over 30 years. We combine a strong fundamental knowledge in cokemaking with the absolute best know-how in construction methods, process control, and operability of the systems we provide.

For new facilities, retrofits and upgrades, WTT can provide Technology, Engineering, and Equipment Supply.

Heat Recovery Coke Plants

- Coke ovens

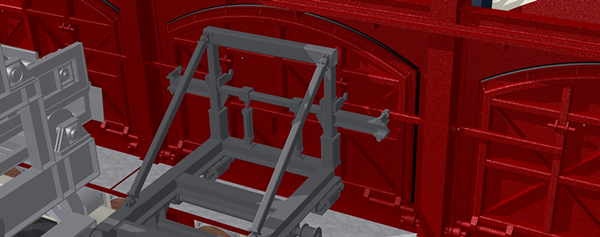

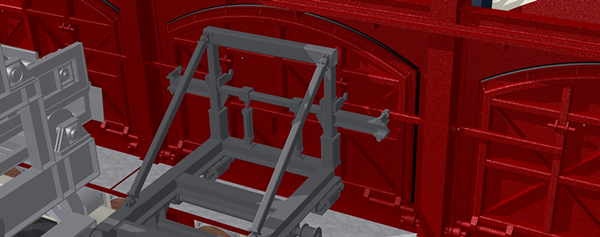

- Pusher/Charger Machines

- Hotcars/Door Machines

- Quenching Systems

- Coke wharves

- Coal and coke handling systems

- Hot gas ductwork

- Emissions control systems

- Plant utilities

- Process analysis and optimization

- Facility Assessments

- Source Inspections

- Owner’s Engineer

By-Product Coke Plants

- Coke plant machinery upgrades

- Pushing Emission Control Systems

- Quench/Wharf Systems

- Coal and Coke Handling Systems

- Balance of Plant Engineering

Other Areas of Specialty

- Direct or indirect fired heaters

- Combustors and thermal oxidizers

- Rotary kilns and stepped hearth furnaces

- Refractory systems

- Stacks and Stack Lids

- Shop fabricated skids and valve trains

- Plant utilities such as plant and instrument air skids

- Materials handling systems

- Belt conveyors, bins, hoppers, chutes

- Industrial fan and pump systems

- Hot and corrosive gas streams

- Refractory lined steel ductwork

- FRP duct and piping systems